Printed Circuit Boards (PCBs) are essential components of modern electronics. They provide a platform for the electronic components to be connected and they can have a single-sided, double-sided, or multilayer design.

In this article, we will explore the different types of PCBs and how each has its unique advantages in various applications. Well look at single-sided boards, which are ideal for simple circuits; double-sided boards with their capacity to increase circuit density; and multilayer boards that allow complex designs due to their multiple layers of circuitry.

Finally, we will discuss why it’s important to consider the type of PCB best suited for your project when designing an electronic device.

Single-Sided PCBs

Single-sided PCBs are the most basic type of printed circuit board, with only one conductive copper layer. This makes them much simpler and more cost-effective in comparison to double-sided and multilayer PCBs, as there is less material used, fewer fabrication processes involved, and a therefore lower price tag.

The main advantage of single-sided boards is that they have higher reliability due to their simple design. They can also be produced quickly since there are relatively few steps needed for production.

However, this simplicity comes at the cost of limited component density; single-sided PCBs cannot support components on both sides so it’s not possible to achieve high levels of complexity or miniaturization. Additionally, routing circuits on a single side requires frequent use of vias which can further limit signal integrity and complicate circuit designs.

Despite this limitation, single-sided boards still have many applications from low-power consumer electronics like MP3 players right through to more complex industrial equipment such as medical imaging systems or aerospace flight control circuitry – though the latter would require additional safety checks due to their critical nature.

Multilayer PCBs

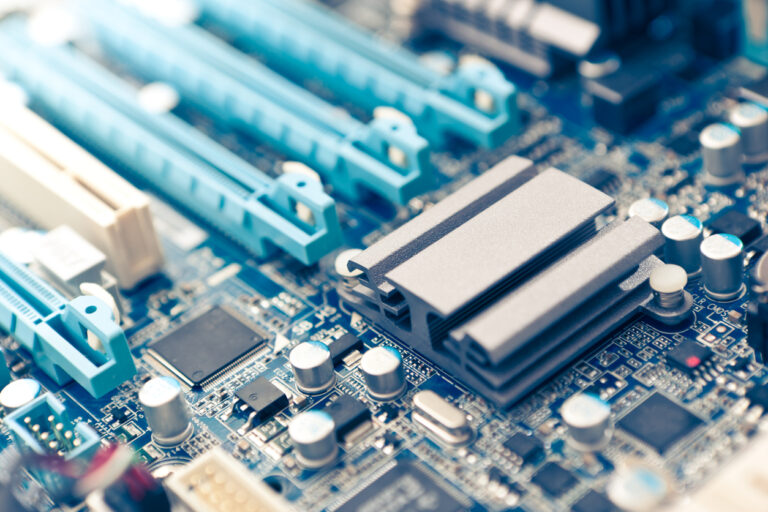

Multilayer PCBs are ideal for more complex projects due to their greater functionality and capacity. They consist of multiple copper layers that are laminated together, with each layer connected using vias or plated through holes.

This allows components to be placed on both sides of the board and also between layers. The signal paths can even cross through multiple planes which enables them to have higher-density designs than single or double-sided boards.

Multilayer PCBs offer users several advantages such as increased component placement options, lower noise levels, better electrical performance, and improved heat dissipation capabilities when compared to other types of PCBs. Additionally, they require fewer interconnections which helps reduce overall assembly time and costs while providing superior reliability in comparison with other types of boards.

Advantages and Disadvantages of Each Type

Single-sided PCBs are the simplest type of printed circuit board, consisting of a single layer of conductive material. They have several advantages over double-sided and multilayer boards, including lower costs for design and production due to their simplicity.

Single-sided PCBs can also be mass-produced quickly with few setup delays or complexities, making them ideal for low-volume applications such as prototyping or hobby projects. The major disadvantage is that they are not suitable for high-density circuits due to the limited number of components that can be placed on one side.

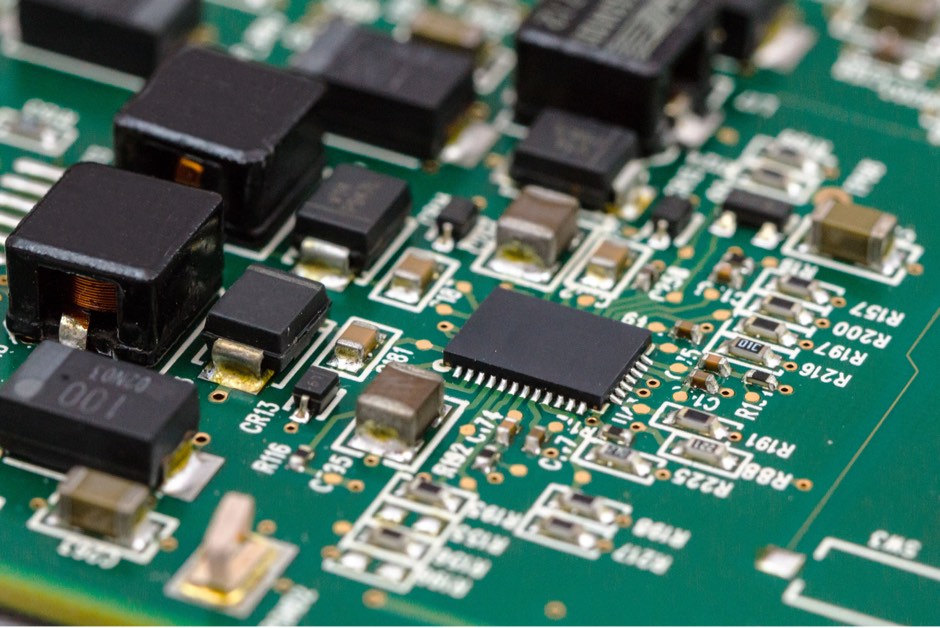

Double-sided PCBs offer more capabilities than single-sided boards by having two layers with copper tracks running in opposite directions on each side. This enables you to place components on both sides which increases the complexity and size potential for your project while still keeping costs relatively low compared to multi-layered boards.

However, double-sided designs require more complex routing techniques so may take longer to produce depending on the size and complexity required. Multilayer Printed Circuit Boards are made up of multiple layers (usually between four and fourteen) sandwiched together using thin insulating materials between each layer.

These allow very dense circuitry with tightly packed component placement but come at a higher cost than either single or double-sided options due to increased complexity in design & manufacturing processes; however, this extra cost can often be offset against reduced assembly time when dealing with larger projects requiring densely populated boards involving many components..

Conclusion

In conclusion, PCBs come in various shapes and sizes to meet different needs. Single-sided boards are the most basic type of circuits used for simple applications while double-sided and multilayer boards offer more complex electronic functions.

As technology continues to advance, it is important to be aware of the Different Types of PCBs available and their capabilities so that you can choose the best solution for your project.