In recent times, the use of laser cutters has revolutionized production processes for sheet and tube fiber. As technology continues to progress, these machines are becoming increasingly advanced in their capabilities and advantages over traditional methods of cutting.

This article will explore four ways that laser cutters make sheet and tube fiber production easier and more efficient than ever before. From increased precision to improved safety standards, the light revolution is here to stay!

Leveraging Laser Cutting Technology in Sheet and Tube Fiber Production

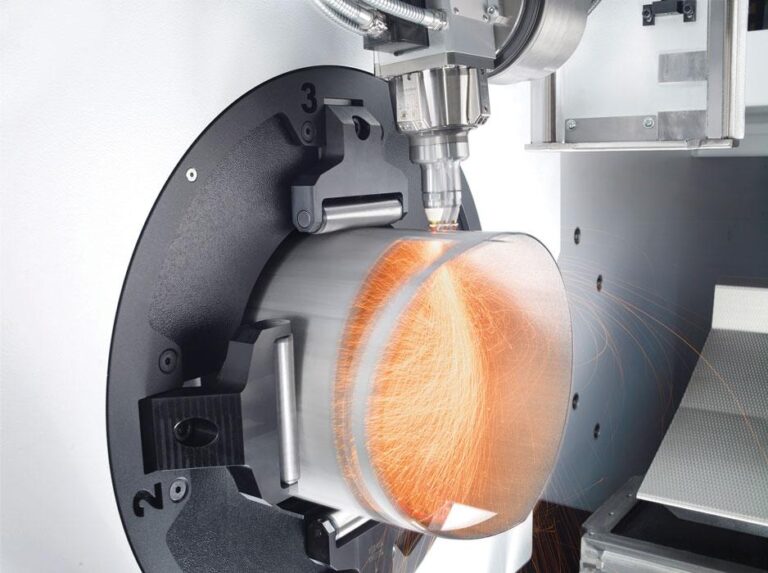

Leveraging laser cutting technology in sheet and tube fiber production has revolutionized the industry, providing businesses with a unique tool that can make their operations more efficient and cost-effective. Laser cutters are capable of producing intricate shapes with high precision and accuracy, making them perfect for creating virtually any type of fiber product.

Additionally, they require minimal setup time compared to traditional methods such as hand saws or mechanical shears. This means that manufacturers can produce larger quantities faster without sacrificing quality.

Plus, laser cutters eliminate the need for manual labor, allowing companies to reduce their labor costs while increasing productivity levels. As a result of these advantages, many companies have switched to laser-cutting technology for sheet and tube fiber production – resulting in greater efficiency and improved profitability across the board.

Streamlining Manufacturing Processes

Laser cutters have also helped streamline manufacturing processes in sheet and tube fiber production. By reducing setup time and allowing for precise cuts, laser cutters can help businesses improve their workflow and decrease the amount of manual labor needed to get a job done.

This not only saves money but also helps to ensure that each product is created with precision and accuracy every time. Additionally, lasers require minimal maintenance, making them ideal for long-term projects that need to be completed quickly without any additional costs or delays.

Laser technology has become an invaluable tool in the industry as it allows manufacturers to produce products faster while still maintaining quality standards – all at a fraction of the cost compared to traditional methods!

Benefits of Using Laser Cutters

Using laser cutters in sheet and tube fiber production offers numerous benefits. With its precise cutting capabilities, laser cutters can produce parts with exacting tolerances that cannot be achieved using conventional cutting methods. This allows for faster completion of jobs and a higher quality end product.

Additionally, the use of lasers eliminates the need for manual handling which reduces stress on workers from strenuous activities such as lifting or moving heavy materials. Laser cutters also offer an improved level of accuracy when compared to other machines, ensuring that each part is produced perfectly every time.

Furthermore, due to their ability to work quickly and accurately without any additional tools or personnel needed, they save businesses both time and money while helping them remain competitive in a fast-paced industry.

Finally, laser cutters are much safer than traditional methods thanks to their enclosed environment which prevents hazardous materials from escaping into the workplace during operations thus protecting employees’ health and safety at all times.

The Future of The Laser Technology

As the world continues to embrace more efficient manufacturing technologies, laser technology is leading the way. In recent years, advances in laser cutters have made sheet and tube fiber production far easier than before.

But what does the future hold for this innovative technology? As industries throughout the globe continue to integrate laser cutters into their operations, improvements in accuracy and speed are expected to follow suit. Not only will these advancements reduce costs across various sectors, but they’ll also make it possible for manufacturers to create custom parts with greater precision than ever before.

Furthermore, as 3D printing becomes increasingly popular within industrial settings, lasers can be used alongside this new technology to further increase efficiency and quality control measures. Beyond its current applications in manufacturing and fabrication processes, researchers are exploring how lasers can be utilized for a variety of other tasks such as surgical procedures or even transportation systems like Hyperloop pods.

With continued research into both laser development and application possibilities, there’s no telling what could come from this revolutionary light source – making it one of the most exciting areas of scientific exploration today!

Conclusion

The laser cutting machine has revolutionized the sheet and tube fiber production industry. It is now easier, faster, and more efficient than ever before.

With a laser cutter, you can quickly cut through various materials with precision and accuracy while preserving their original shape and size for large-scale projects. Not only does it reduce waste but also saves time and money in the process.

The light revolution has made sheet and tube fiber production much easier compared to traditional methods of fabrication.