In the ever-evolving landscape of industrial production, the adoption of advanced technologies is no longer a luxury but a necessity for staying competitive. Among these, the robot welder stands out as a transformative force, fundamentally changing how products are made across the UK. This article explores the growing impact of robotic welding, its benefits, and what it means for the future of British manufacturing.

A New Era of Precision and Efficiency

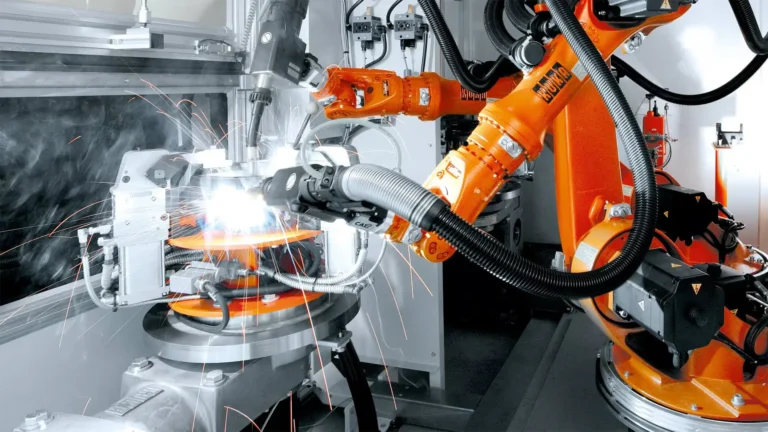

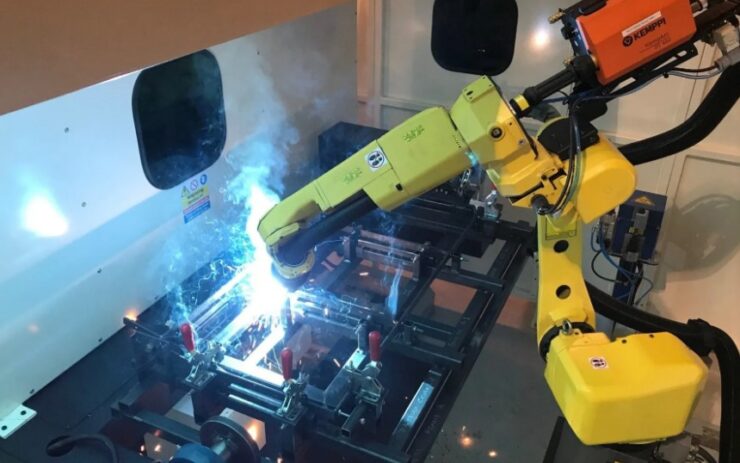

For decades, welding has been a skilled craft, reliant on human precision and experience. While human welders remain indispensable, the integration of robotic systems offers a compelling alternative for repetitive, high-volume, or hazardous tasks. Modern robot welders combine sophisticated automation with precise control, capable of executing welds with a level of consistency and accuracy that is difficult, if not impossible, to achieve manually over extended periods.

The benefits are manifold. Factories employing robotic welding often report significant increases in productivity, reduced material waste due to fewer errors, and improved product quality. The speed at which these systems can operate also translates into shorter lead times, allowing British manufacturers to respond more swiftly to market demands.

Enhancing Workplace Safety

One of the most compelling arguments for the widespread adoption of robot welders is the enhancement of workplace safety. Welding environments can expose workers to a range of hazards, including intense heat, UV radiation, fumes, and repetitive strain injuries. By deploying robots, businesses can remove human operators from these dangerous conditions, allowing them to focus on supervisory roles, programming, and maintenance. This not only protects employees but also contributes to a healthier and more sustainable working environment.

The Economic Imperative for UK Businesses

In a globalised economy, British manufacturers face stiff competition. Investing in automation, particularly in areas like welding, can provide a crucial competitive edge. While the initial outlay for a robotic system might seem substantial, the long-term returns on investment are often considerable. The ability to produce higher quality goods more efficiently and with lower labour costs per unit makes a strong economic case for embracing this technology.

Automation also helps alleviate growing labour shortages in skilled trades—a challenge many manufacturers are currently facing. By complementing human talent with robotic systems, businesses can maintain output levels despite hiring difficulties, while also preserving the knowledge of experienced welders through programming and oversight roles.

Moreover, integrating advanced systems demonstrates a commitment to innovation, which can be attractive to clients and investors alike. For those looking to explore the possibilities of robotic welding and system integration, further information can be found at this link: robot welder.

The Future is Automated

The trend towards increased automation in British manufacturing is set to continue, with robot welders playing a central role. As technology advances, these systems will become even more sophisticated, capable of handling a wider range of materials and complex geometries with greater adaptability. The collaboration between human ingenuity and robotic precision promises a future where British-made goods are synonymous with cutting-edge quality and efficiency, solidifying the UK’s position as a leader in advanced manufacturing.