Microchannel coils have emerged as a revolutionary technology in the field of thermal management and heat exchange. Their compact design and enhanced surface area make them increasingly popular in various applications, from HVAC systems to industrial cooling processes.

This article delves into their efficiency, benefits, and practical applications.

The Design Advantage

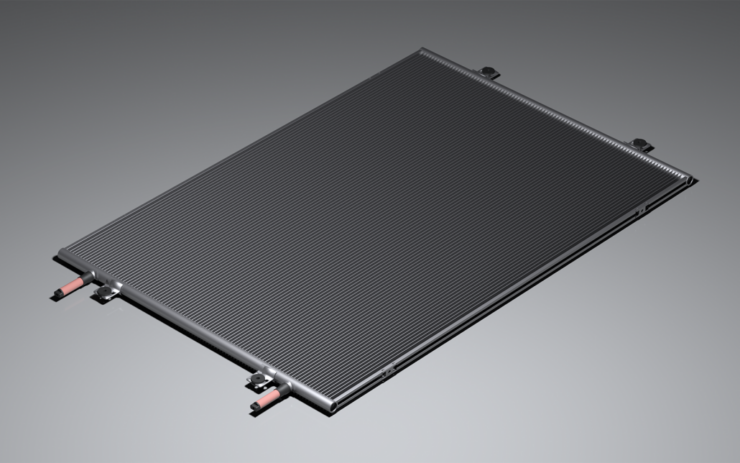

Microchannel coils consist of multiple small channels that allow refrigerant to flow through, maximizing heat exchange efficiency. The geometry of these coils contributes significantly to their performance, as the reduced volume of refrigerant required leads to faster heat transfer rates.

For instance, in commercial refrigeration, a microchannel coil can optimize the cooling process, requiring less energy while maintaining temperature stability. Traditional coils, in contrast, may use more refrigerant for similar outcomes, leading to higher operational costs.

Heat Exchange Efficiency

The essential function of any heat exchanger is to facilitate effective thermal transfer between two fluids. Microchannel coils excel at this due to their increased surface area-to-volume ratio, which enhances heat exchange rates. Research indicates that these coils can outperform traditional tube-and-fin designs by up to 30% in terms of heat transfer efficiency.

Moreover, the microchannel coil structure allows for a more uniform temperature distribution across the coil, which is critical for preventing hotspots and ensuring consistent performance. This uniformity is particularly beneficial in applications where precise temperature control is essential, such as in pharmaceutical manufacturing like Kaltra.

Applications Across Industries

The versatility of microchannel coils extends to various sectors. In automotive applications, for example, they have been utilized in vehicle air conditioning systems, offering lighter weight and improved efficiency compared to old systems. The automotive industry’s push for reduced emissions aligns perfectly with the efficiency gains provided by such coils.

In the HVAC sector, microchannel technology has transformed the design of condensing units and evaporators, leading to systems that are not only more efficient but also occupy less physical space. This is particularly advantageous in urban settings where space is at a premium.

Environmental Impact

The efficiency of microchannel coils also contributes positively to environmental sustainability. Reduced energy consumption translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change. Furthermore, the ability to operate with lower refrigerant volumes minimizes the impact of refrigerant leaks, addressing one of the industry’s significant environmental concerns.

Economic Benefits

Investing in microchannel coil technology can yield substantial economic returns over time. Although the initial costs may be higher than traditional systems, the energy savings and reduced refrigerant usage quickly offset these expenses. Maintenance costs can also be lower due to the robustness of the microchannel design, which is less prone to clogging and corrosion.

As industries increasingly focus on energy efficiency and sustainability, microchannel coils present a forward-thinking solution that meets modern needs while ensuring operational excellence.

A Result

The integration of microchannel coils into various applications showcases their remarkable efficiency and adaptability. From improved heat exchange capabilities to significant environmental benefits, these coils are reshaping industries.

As technologies evolve, the focus on optimizing energy use while minimizing environmental impact will only amplify the importance of microchannel coils in the future landscape of thermal management.