Installing, testing, and maintaining motor starters is an important part of keeping any manufacturing or industrial business running smoothly. Taking the necessary steps to ensure you are using the best practices for these tasks will help keep your operation efficient and reliable.

This article will explore some of the key considerations when it comes to installing, testing, and maintaining motor starters to get the most out of them. From examining how best to install a starter correctly to ensure that regular maintenance takes place, readers can learn ways in which they can optimize their equipment usage and performance.

With careful consideration taken into account throughout each step of the installation, testing, and maintenance process, businesses have an opportunity to make sure their equipment is operating as efficiently as possible at all times.

Pre-Installation Procedure

Before installing motor starters, it is important to take the necessary steps to ensure a successful installation. This pre-installation procedure includes familiarizing yourself with local safety codes and regulations as well as performing any required inspections.

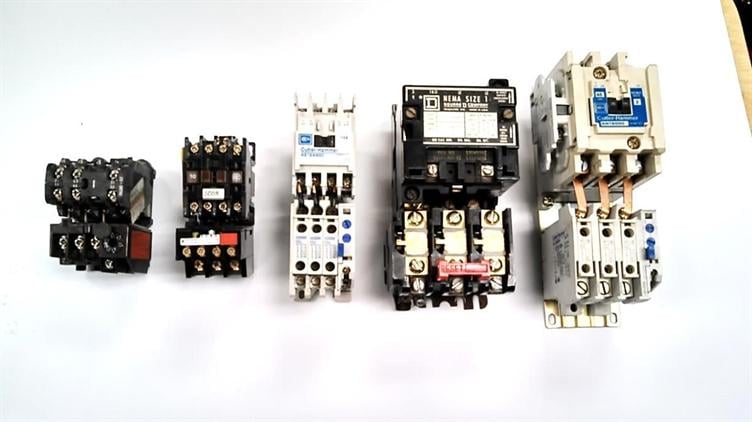

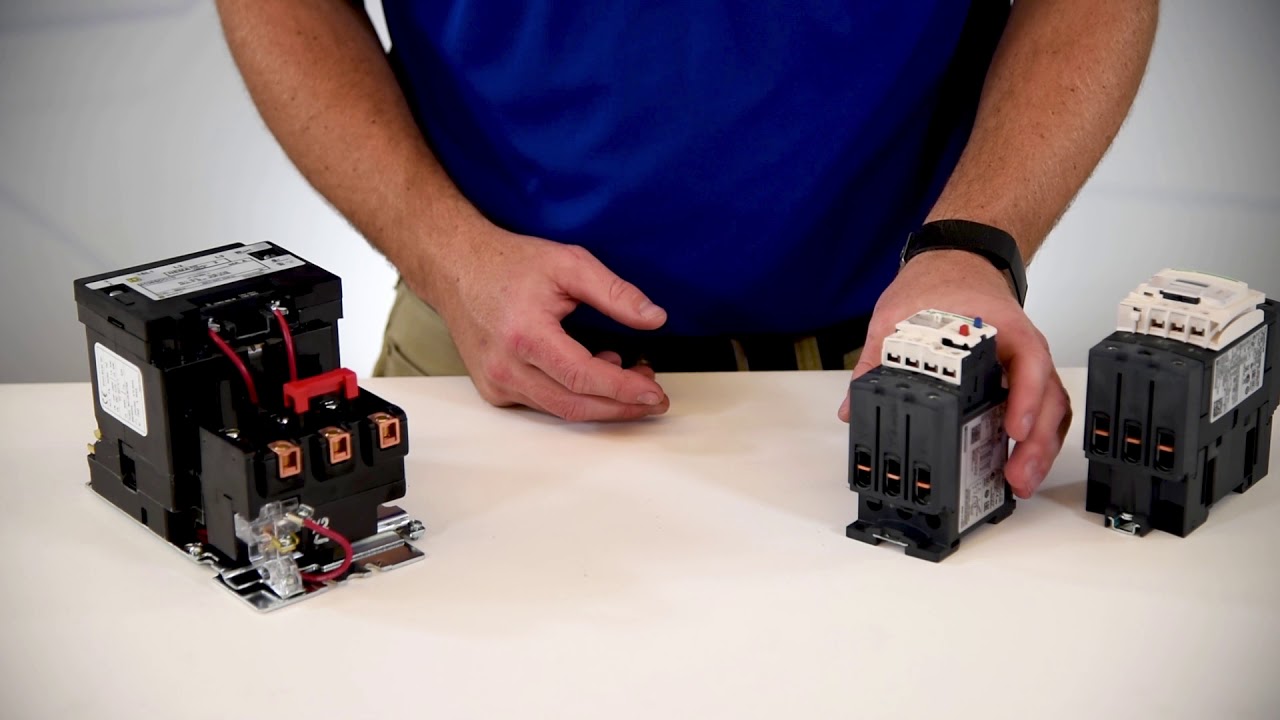

Additionally, you should make sure that all of the components are appropriate for the application including choosing the proper size starter and confirming compatibility between components. To prevent potential problems during installation or operation, it is essential to review user manuals and wiring diagrams before beginning work on any electrical systems. Lastly, it is also important to test each component before integrating them into a larger system to confirm their performance accuracy and functionality.

Taking these steps will help ensure that your motor starter installation goes smoothly.

Installation Process

Installing a motor starter can be complicated and technically demanding. But, with the right knowledge and tools, it’s possible to install a reliable system that will last for years.

To ensure the successful installation of your motor starter, it is important to follow best practices throughout the process. Before beginning installation, make sure you have all the necessary components on hand and read through any instructions provided by the manufacturer carefully.

Once everything has been double-checked, begin by connecting power wires according to local codes and regulations before mounting the motor starter in its designated area. After securely attaching all components of the system, test each connection individually to guarantee proper function before turning on the power for full tests of both individual parts as well as their integration into one cohesive unit.

Finally, once everything is installed correctly – remember to periodically inspect your motor starter for wear or damage caused during normal operation – doing so can help extend its lifespan significantly!

Maintenance Practices

When it comes to maintenance practices for motor starters, there are several key steps to ensure they remain in top working condition. First and foremost, regularly inspecting the starter is a must.

Look out for any signs of wear or damage that may lead to future malfunctioning. Additionally, checking all connections and tightening bolts helps maintain the integrity of the unit as well as make sure all components are secure and functioning properly.

Furthermore, cleaning off dust and debris from around the terminal blocks helps prevent corrosion caused by buildup over time. In addition, periodically lubricating moving parts ensures that your starter will keep running smoothly without any grinding or sparking due to insufficient lubrication levels.

Lastly, replacing worn-out contacts prevents electrical arcs from forming which can cause significant damage both internally and externally if left unchecked for too long. These simple but necessary maintenance practices will help you get the most out of your motor starter while also extending its life expectancy significantly when done regularly.

Make sure you follow these best practices whenever possible to avoid costly repairs down the line!

Conclusion

In conclusion, following the best practices for installing, testing, and maintaining motor starters will help ensure that they are functioning properly. Installing it correctly is essential for safety and reliability.

Testing should be done regularly to make sure the starter is working efficiently and consistently. Finally, regular maintenance such as cleaning electrical contacts can extend its life by preventing wear on the starter’s components caused by dirt or corrosion.

Similarly, it’s important to check your car alternator periodically to ensure it is providing enough power to keep your vehicle running smoothly. Taking these steps can save you from costly repairs in the long run.